Description

Japan mechanical delay buffer air column bag production line, suitable for PE co-extruded film and other coil production various buffer air column bags, buffer air cushion, filled air bags. The products produced are low-cost, space-saving, recyclable, and reduce the packaging process, saving manpower, pollution-free, and providing seismic protection for long-term storage and non-leakage.

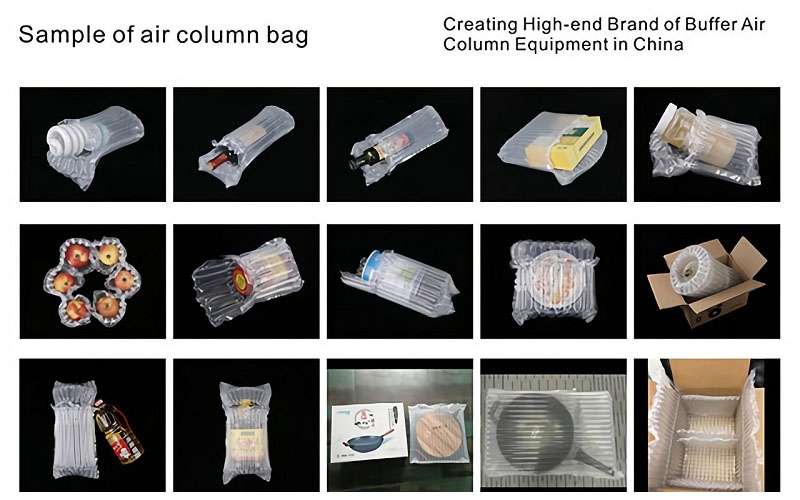

Application

Widely used in various packaging fields, such as electronic products, ceramics, precision instruments, furniture, lighting products, auto parts, toner cartridges, red wine, milk powder, express logistics and other industries.

Technical Parameters

A machine column speed (m / min): 10-25 (speed adjustable)

B mechanism bag speed (per/min): less than or equal to 50

Maximum film width (mm): 1180

Maximum roll diameter (mm): ¢450 (about 1500 m)

Retracting and unwinding shaft diameter (mm): ¢74mm

Total power (kW): 14.5+3.2 (A machine + B machine)

Machine net weight (kg): 2100+1200+700 (A machine + B machine + triangle machine)

Machine dimensions (length × width × height) (mm)

A machine: 6800 × 1800 × 1470

B machine: 5800×1350×1380

Triangle machine: 1700 × 1400 × 1500

Machine noise (decibel): ≤ 65 decibels

Bag yield rate (percentage): ≥97%

Sealing pressure (Newton/mm 2): 15

Power type : 220V 50Hz

Packaging film material: PE co-extruded film, etc.

Features

1.The main control circuit is controlled by imported PLC and inverter. The man-machine interface is intuitive and convenient to operate.

2. Any fixed length is ready to use, convenient and simple, photoelectric automatic tracking, accurate and stable.

3. The whole machine adopts inverter control, the frequency conversion range is wide, the speed adjustment range is large, and the stepless speed change is realized. Ready to use, matching perfectly.

4. The double correcting device is divided into the film to correct the deviation, and the lower film is used to correct the two sets of mechanisms. The function is to automatically correct and adjust the film deviation through photoelectric detection.

5. The easy-to-tear cutter device is mainly used for the production of sheets. After the sheet is pressed, the sheet is cut and easily torn according to the length set by the user. The volume can be torn off according to the cutting mark when the user uses it, which is convenient and practical.

Address : No.4 Yangda Road, Xiyong Area, Lunjiao Town, Shunde District, Foshan City, Guangdong Province, China (P.S.code:528308)

Tel : 0757-22817002

Website : WWW.ZTECHMC.COM

copyright : ZTECH

Powered by : sowho.cn