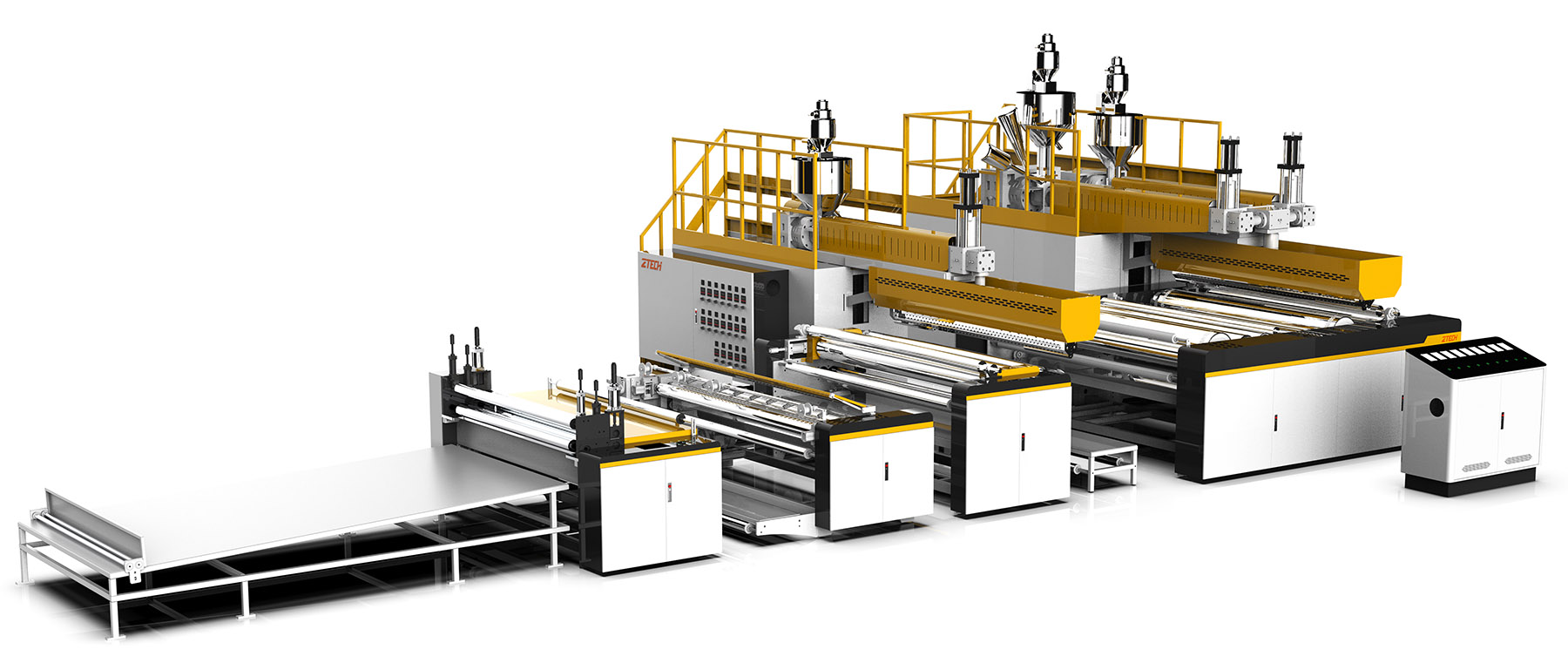

Description

PP bubble board machine or PP bubble machine, the product is used widely in constructions and decorations.The hollow grid plate die and feedblock can make UV protection on both sides. It have a high impact strengh, good weather resistance and UV protection.

The product is composed of 2~3 layers of plastic sheet and short-fiber terylene needling cotton. It ismainly used as decorative board of the automobile ceiling and indoor decorative materials. It performs the features of sound insulation, temperature keeping, and shockproof.

Application

The production line consists of forming, compounding, stress elimination, trimming, and cutting parts, each part is equipped with an inverter for stepless speed adjustment, the whole production line can be adjusted synchronously. The production line possesses other features, such as easy for operation and maintenance, convenient for buying wearing parts, reliable product quality, and etc.

Features

1. Good water resistance. Even if it is completely immersed in water for many days, it will not be deformed by moisture. It will not rot and rust.

2. It is not compatible with cement, sticky, easy to demould after construction, and will not be deformed by cement adhesion.

3. High construction efficiency and good quality. The surface of the building with which it is constructed is smooth and flat, and no secondary modification is necessary.

4. Saved the process and improved the construction efficiency. At the same time, when the template is processed, the surface of the template can be pretreated to obtain the desired wall pattern.

5. Light weight and convenient construction.

6. Long life and repeated use. The final damaged plastic formwork can still be crushed again, re-processed into a new formwork, saving resources and meeting the requirements of "green industry".

7. Good insulation, which is conducive to shortening the construction period.

8. Various treatments can be carried out by adding wood, and welding can also be carried out, so that secondary processing can be flexibly performed at the construction site.

Model: ZT150-PP PP Bubble machine

|

Maximum width (mm) |

1500 |

|

Production Capacity (kg/hr) |

300kg--Max. 600kg/hr |

|

Range of film thickness |

3-10mm |

|

Main screw diameter (mm) |

Φ90mm + Φ90mm |

|

Secondary screw diameter (mm) |

Φ90mm |

|

Temperature control region |

27 |

|

Power of main motor (kW) |

45KW+45KW |

|

Power of secondary motor (kW) |

45 |

|

Power Supply |

380V,50HZ,3 PHASES(Can be customized according to different countries) |

|

Total power (kW) |

160 |

|

Heating power (kW) |

106 |

|

Effective power (kW) |

48 |

|

Weight (kg) |

12000 |

Address : No.4 Yangda Road, Xiyong Area, Lunjiao Town, Shunde District, Foshan City, Guangdong Province, China (P.S.code:528308)

Tel : 0757-22817002

Website : WWW.ZTECHMC.COM

copyright : ZTECH

Powered by : sowho.cn